- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

Aluminium Extrusion Double Puller Single Puller Servo Motor Synchronous System

Aluminium Extrusion Double Puller Single Puller Servo Motor Synchronous System Aluminum Extrusion Cooling Tables/Handling Tables in Aluminum Extrusion Machine

Aluminum Extrusion Cooling Tables/Handling Tables in Aluminum Extrusion Machine Best Selling Aluminium Profile Cooling Bed Machine with Fans Cooling for Aluminium Extrusion

Best Selling Aluminium Profile Cooling Bed Machine with Fans Cooling for Aluminium Extrusion Aluminum Extrusion Profile Metal Handling Table Machine Equipment Equipped with Sizing Platform

Aluminum Extrusion Profile Metal Handling Table Machine Equipment Equipped with Sizing Platform- All new products

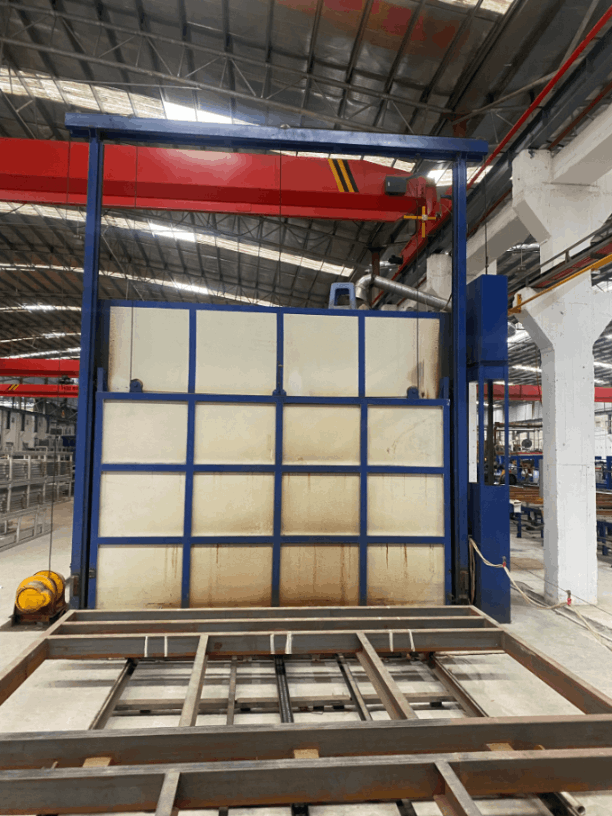

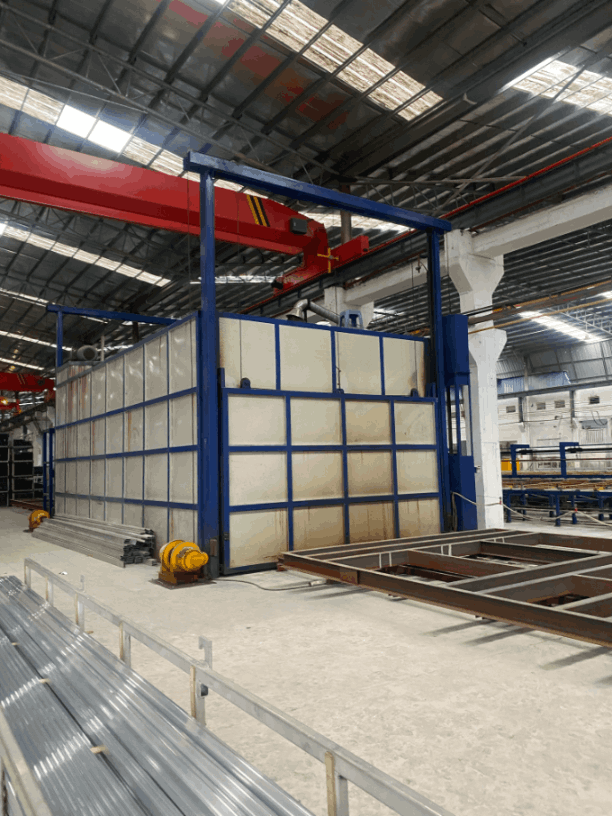

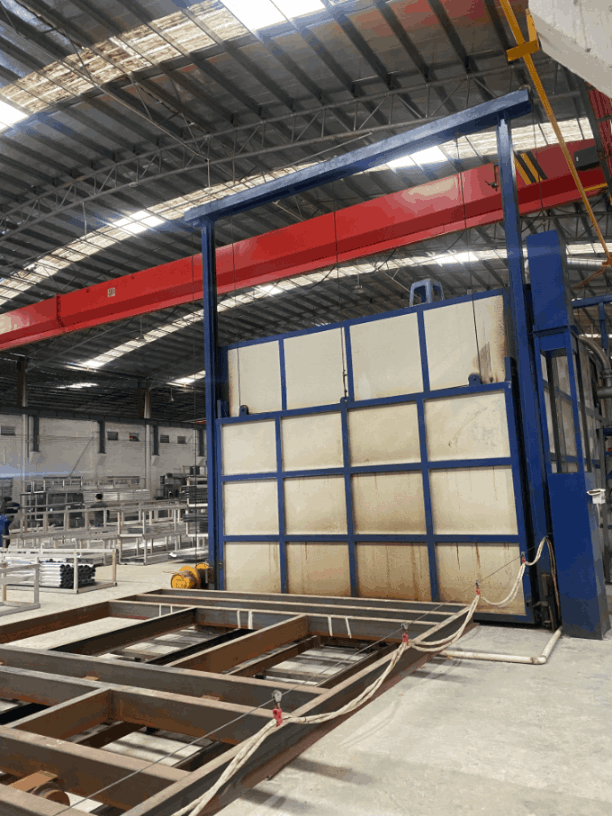

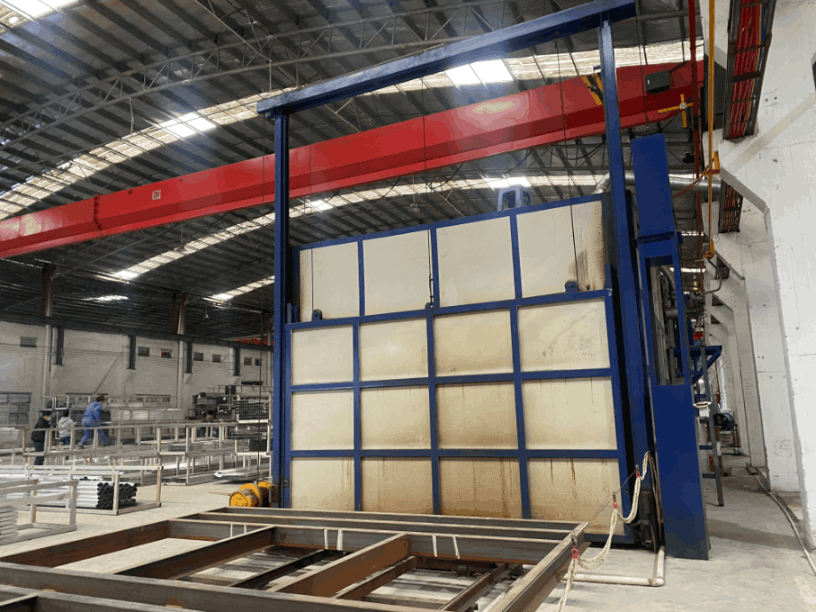

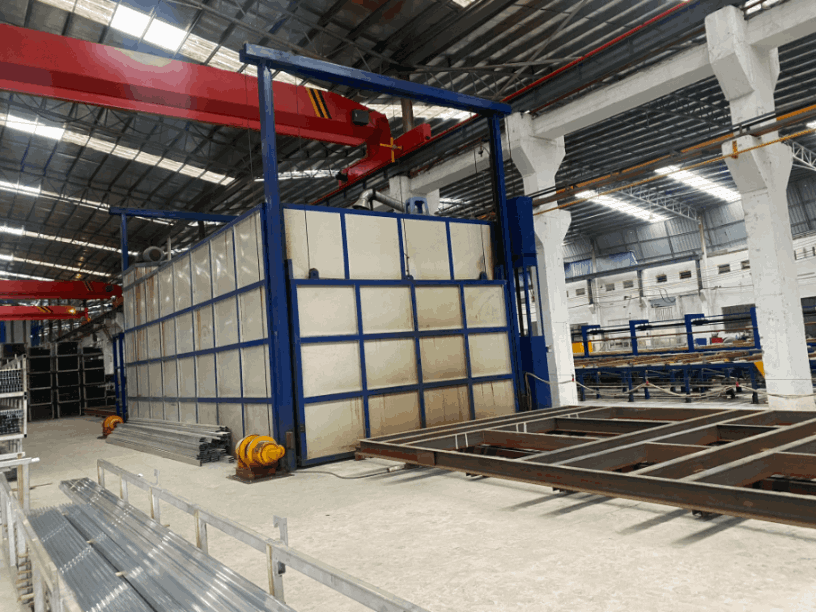

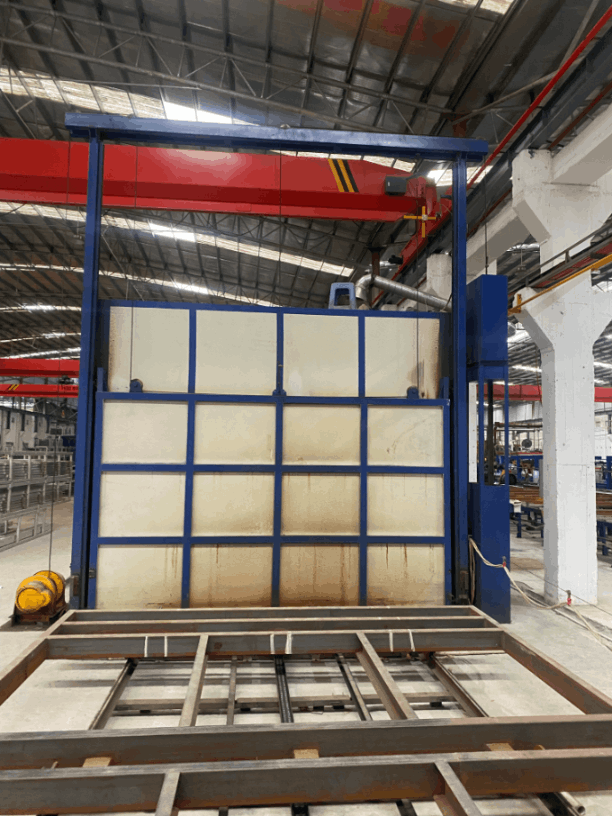

Aging Oven for Aluminum Extrusion Profile

Foshan Nanhai Yanming Thermal Energy Equipment Technology Co., Ltd. stands at the forefront of the Aging Oven for Aluminum Extrusion Profile sector, known for our pioneering solutions and exceptional quality. Our product line, including advanced Aging Oven for Aluminum Extrusion Profile, precision cutting saws, and others, caters to the evolving needs of the aluminum industry. At Yanming, we are dedicated to enhancing your operational efficiency and precision, backed by our commitment to innovation, customer satisfaction, and excellence.

Model:YM-SSL

Send Inquiry

Our state-of-the-art Aging Oven for Aluminum Extrusion Profile is equipped with advanced temperature control systems to ensure uniform heat distribution and precise aging of aluminum profiles. By carefully managing the aging cycle, our Aluminum extrusion profile Aging oven optimizes the physical properties of the aluminum, achieving an ideal balance of strength and flexibility. This technology is crucial for producing high-quality aluminum products used in demanding applications, such as transportation, building facades, and industrial machinery.

Yanming Aging Oven for Aluminum Extrusion Profile Parameter (Specification)

|

The maximum length of profiles placed in the furnace(mm) |

7000MM |

|

Furnace size (L×W×H)mm |

10000MM*2200MM*2100MM |

|

fuel |

gas |

|

Total installed equipment maximum capacity |

55kw |

|

Calorific value of fuel |

8400kcal/m³ |

|

Material trolley frame steel (National standard) |

12# channel steel |

|

Main furnace bottom frame steel (national standard) |

16# channel steel |

|

Trolley chain frame type steel |

Self-folding +10# channel steel |

|

Installation position of circulating fan |

Furnace top |

|

Material trolley traction power |

3kw |

|

The thickness of furnace insulation layer is 220mm |

High temperature loose cotton |

Yanming Aging Oven for Aluminum Extrusion Profile Feature And Application

The Aging Oven for Aluminum Extrusion Profile we offer is distinguished by its advanced safety features and robust construction, ensuring long-term reliability and operator safety. With automated process monitoring and alarm systems, it delivers peace of mind alongside high-quality aging treatment. This Aging Oven for Aluminum Extrusion Profile makes it a valuable asset for manufacturers of aluminum profiles used in high-stakes applications such as infrastructure projects, where material failure is not an option, and in high-precision machinery, where component integrity is critical.

Yanming Aging Oven for Aluminum Extrusion Profile Details

The Aging Oven for Aluminum Extrusion Profile we manufacture integrates seamlessly into existing extrusion lines, thanks to its modular design and adaptable process parameters. It features an automated loading and unloading system, minimizing manual handling and enhancing production safety. This system is critical for producing aluminum extrusions that require precise mechanical properties, such as those used in aerospace components, electronic casings, and precision engineering, where quality and repeatability are paramount.